Air Lubrication Cruise Ships

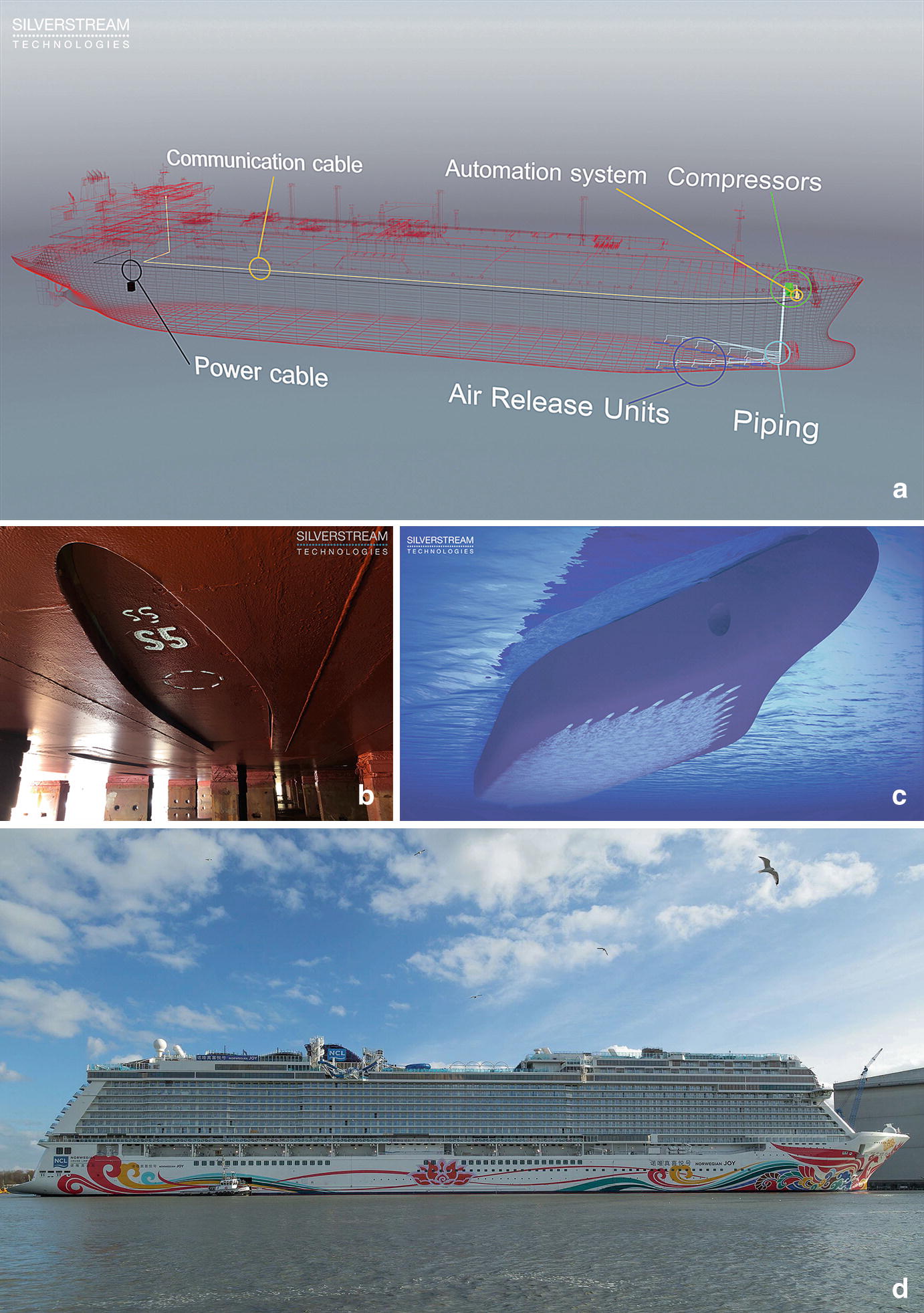

Silverstreams Air Lubrication System creates a carpet of microbubbles that coat the entire flat bottom of the vessel.

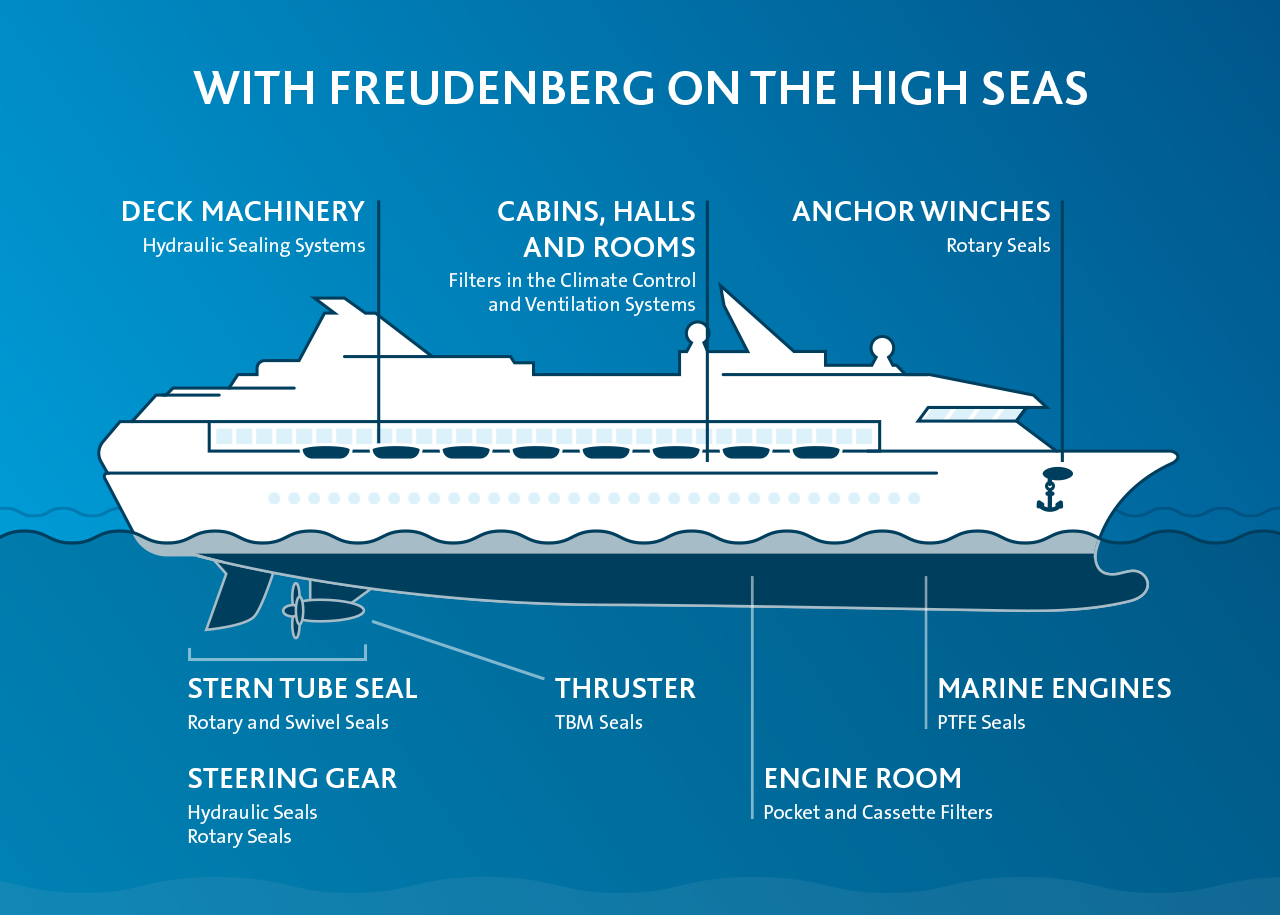

Air lubrication cruise ships. The air-bubble lubrication system introduced on Quantum is one of the means by which Royal Caribbean steadily improves fuel efficiency on each new ship launched. The most recent installation of MALS has been on two AIDA Cruise vessels in 2016 and 2017. A newbuild Carnival Corporation Excel-class cruise ship currently known as hull S717 is to be fitted with an air lubrication technology system from Silverstream Technologies following the agreement of a contract with Meyer Werft Shipyard.

The collision bulkhead is to be penetrated only as specified therein. We work with leading technology and equipment providers to ensure our technology offering remains at the forefront of clean technologies currently on the market. MHI will install its innovative Mitsubishi Air Lubrication System MALS on two large cruise ships to be built for the AIDA Cruises a German brand of Carnival Corporation plc.

Anne Kalosh Oct 04 2021 The Silverstream System uses a series of air release units in the flat bottom of a vessel to generate a rigid carpet of microbubbles that travel the full length of the hull. Carnival Corporation has committed to installing Silverstream Technologies fuel-saving air lubrication system to its Excel-class cruise ship currently known as hull S717. By covering the ships bottom like a carpet with fine bubbles blown from the ships bottom using a blower the system reduces frictional resistance between the ship hull and seawater as the ship cruises.

Fuel savings of 5 to 7 are expected. Air Lubrication System is a method to reduce the resistance between the ships hull and seawater using air bubbles. This carpet effectively reduces frictional resistance between the hull and.

Quantum for example is 20 percent more fuel efficient per available passenger day than her predecessors. Ii The Air Lubrication System plans and arrangements are to clearly show the space it occupies and. Mitsubishi has developed its own so-called air lubrication system claiming to reduce power and fuel consumption by up to 10 percent.

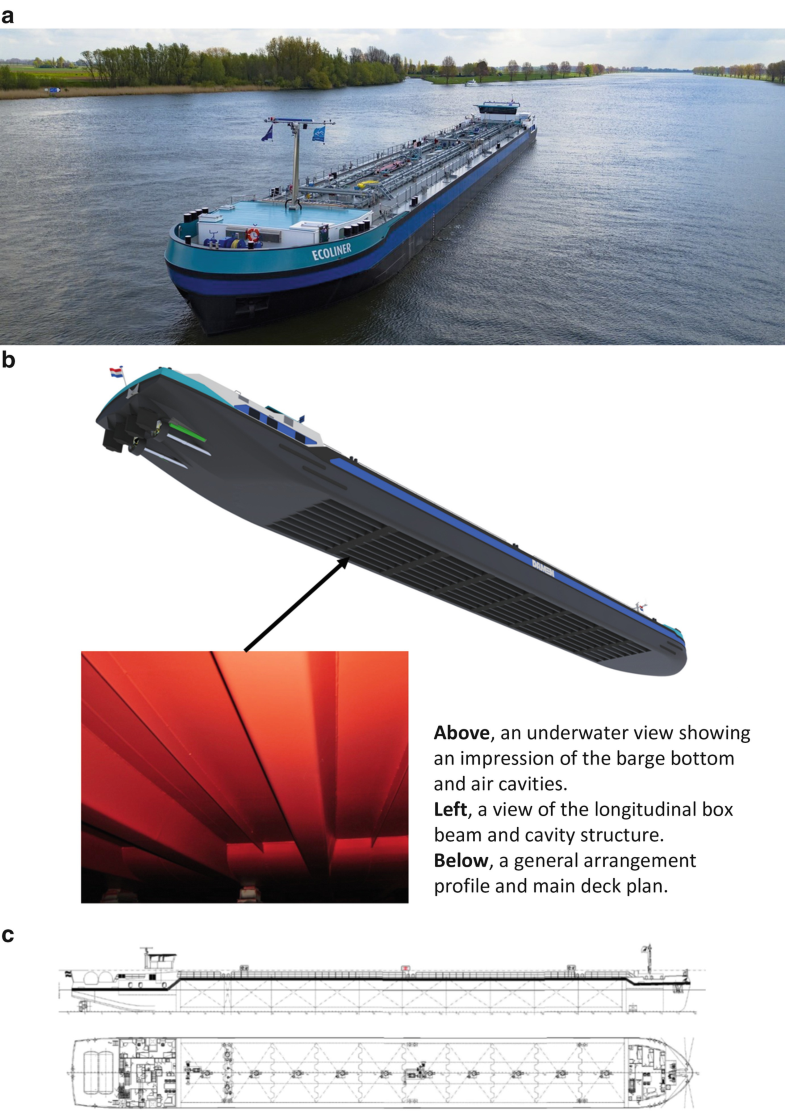

PELS studied numerical analysis of these techniques verified with model testing results. Tokyo June 6 2012 - Mitsubishi Heavy Industries Ltd. The national Dutch research project Project Energy-saving air-Lubrication Ships PELS was formed in 1999 to study the three air lubrication techniques air bubble air layer and air cavity.